| Model | Thickness | Specification | Fire-proof level |

| DL240 | 4mm | Surface aluminum: 0.3mm/Back aluminum: 0.3mm | A2 |

| 4mm | Surface aluminum: 0.5mm/Back aluminum: 0.5mm | A2 | |

| 4mm | Surface aluminum: 0.3mm/Back aluminum: 0.3mm | B1 | |

| 4mm | Surface aluminum: 0.5mm/Back aluminum: 0.5mm | B1 |

| Model | Thickness | Specification | Fire-proof level |

| DL240 | 4mm | Surface aluminum: 0.3mm/Back aluminum: 0.3mm | A2 |

| 4mm | Surface aluminum: 0.5mm/Back aluminum: 0.5mm | A2 | |

| 4mm | Surface aluminum: 0.3mm/Back aluminum: 0.3mm | B1 | |

| 4mm | Surface aluminum: 0.5mm/Back aluminum: 0.5mm | B1 |

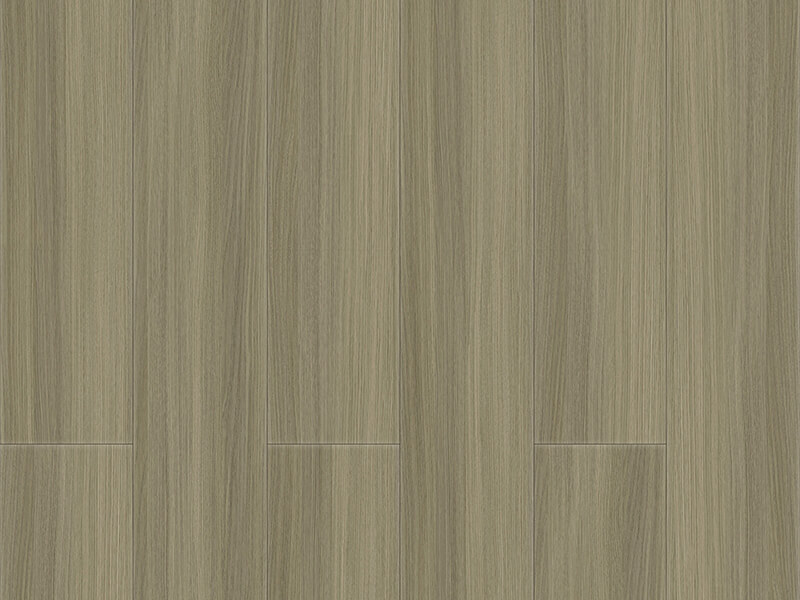

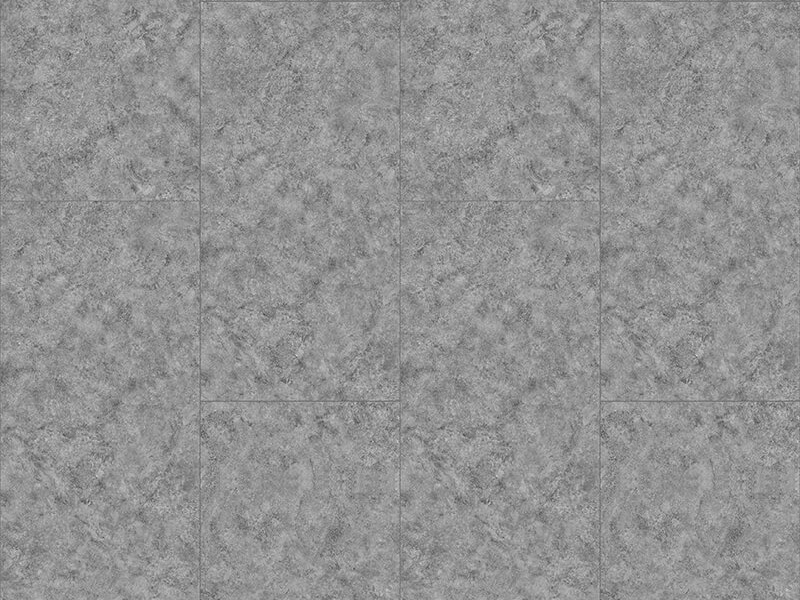

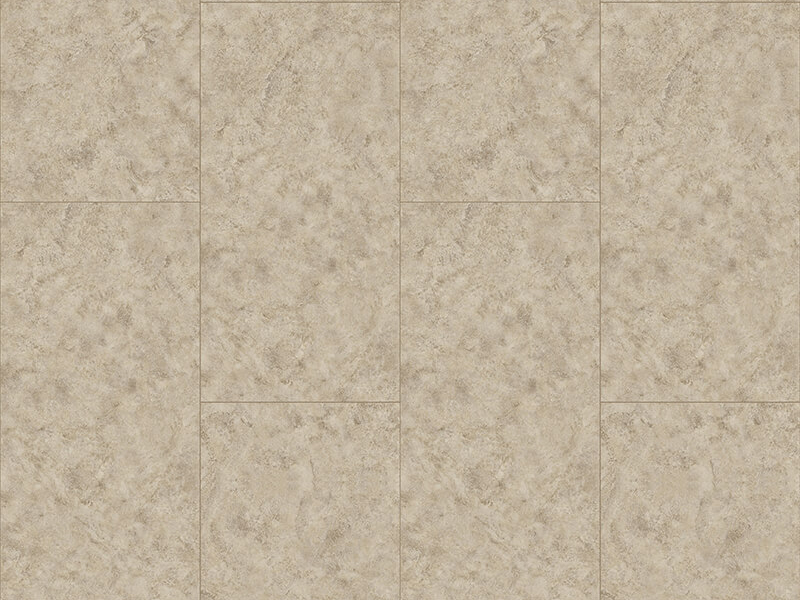

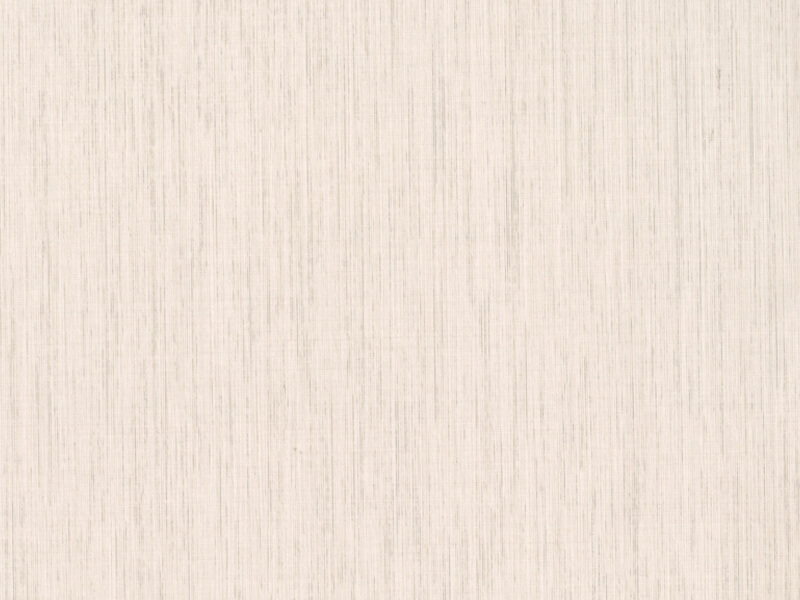

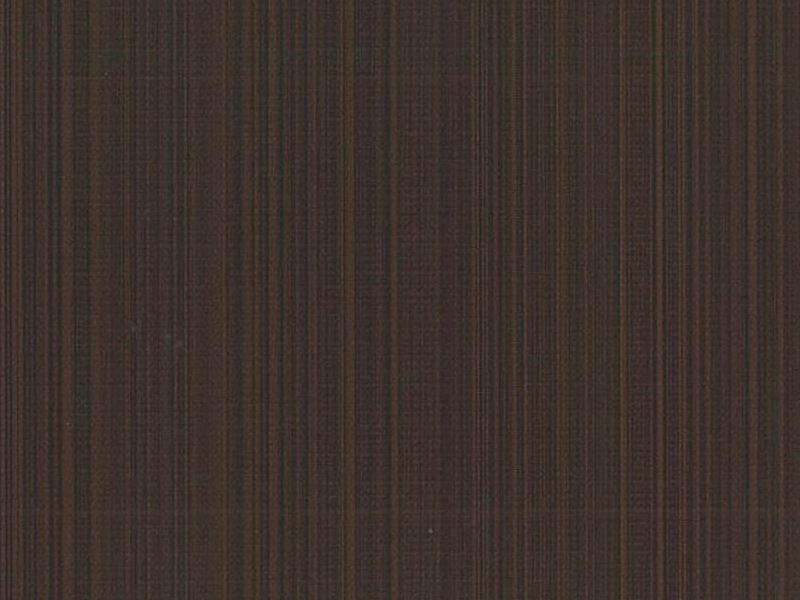

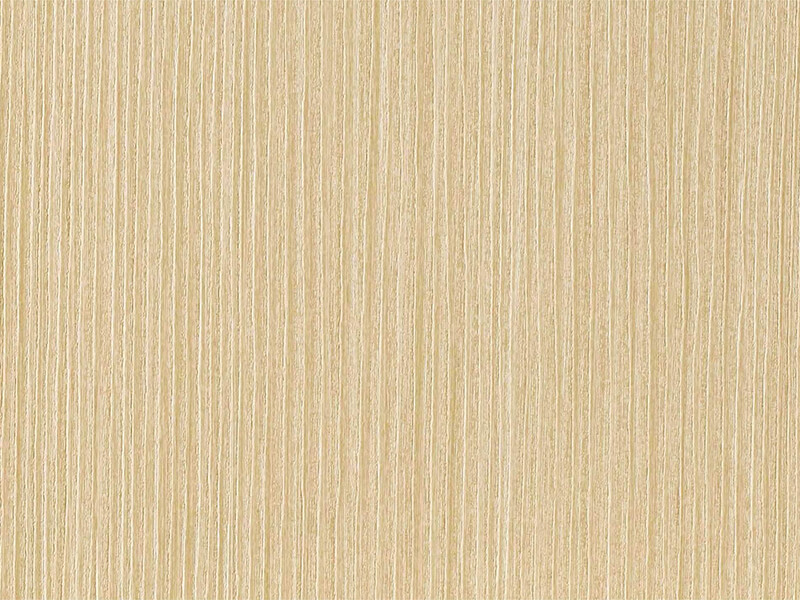

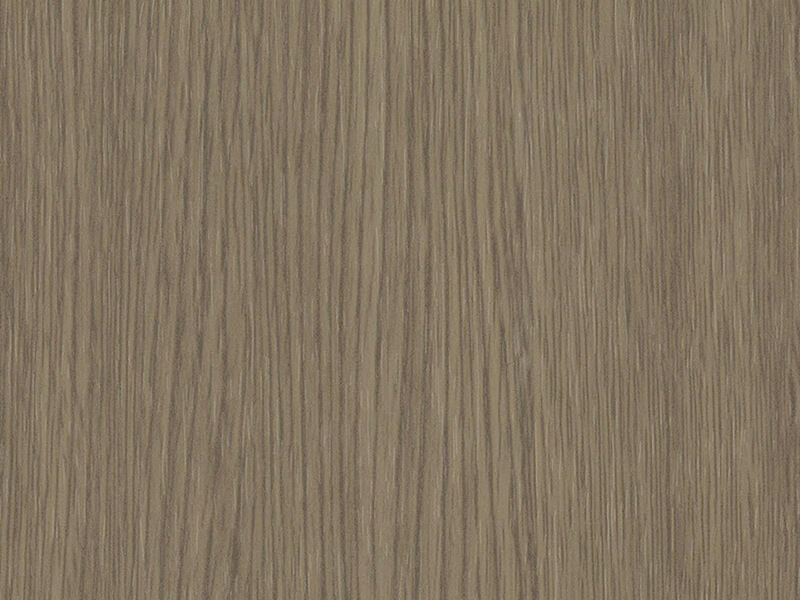

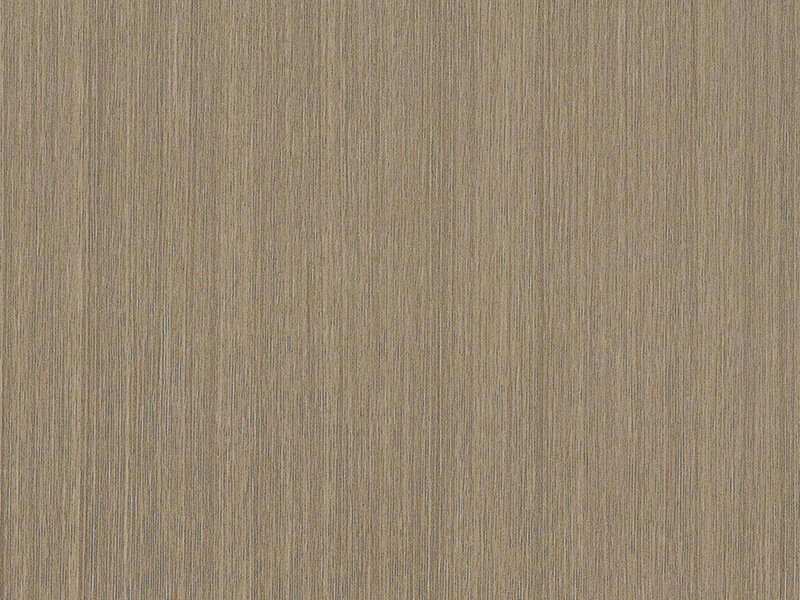

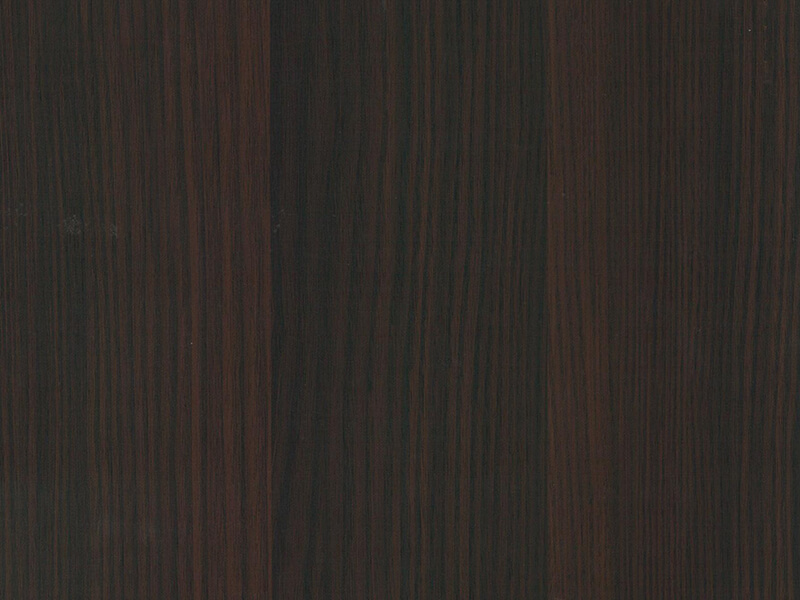

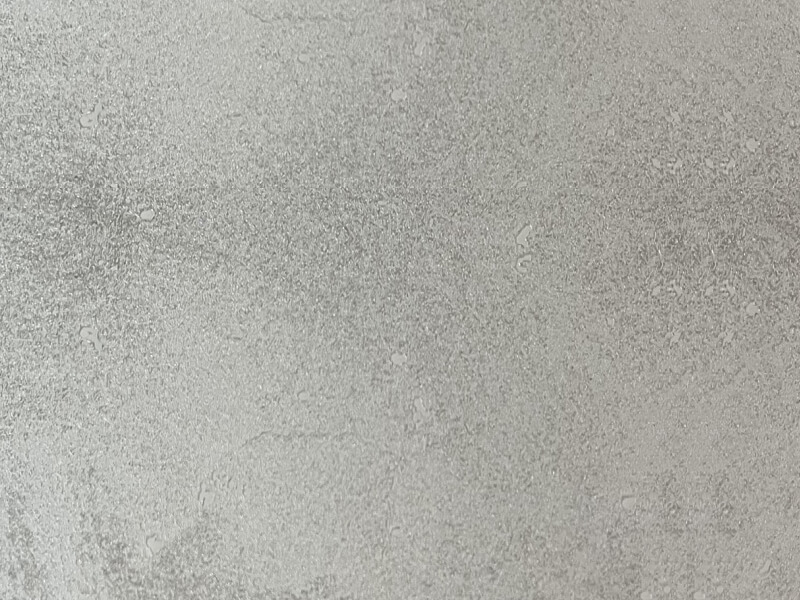

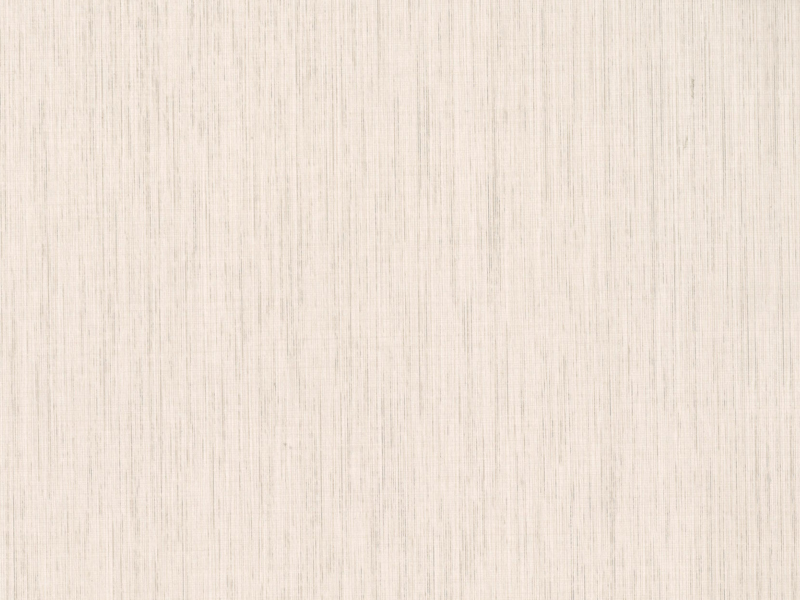

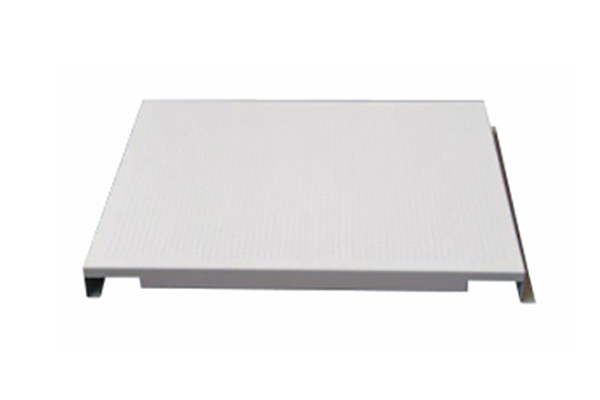

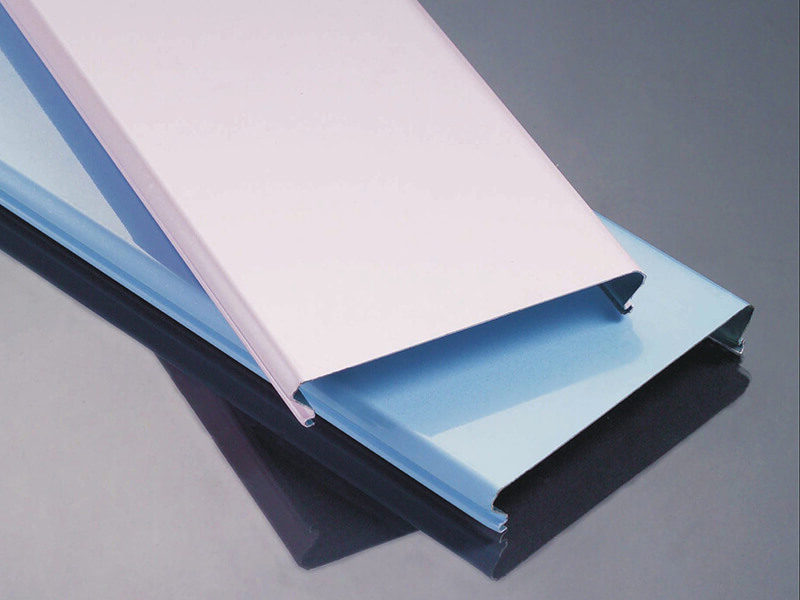

Product Description

Detail Shows

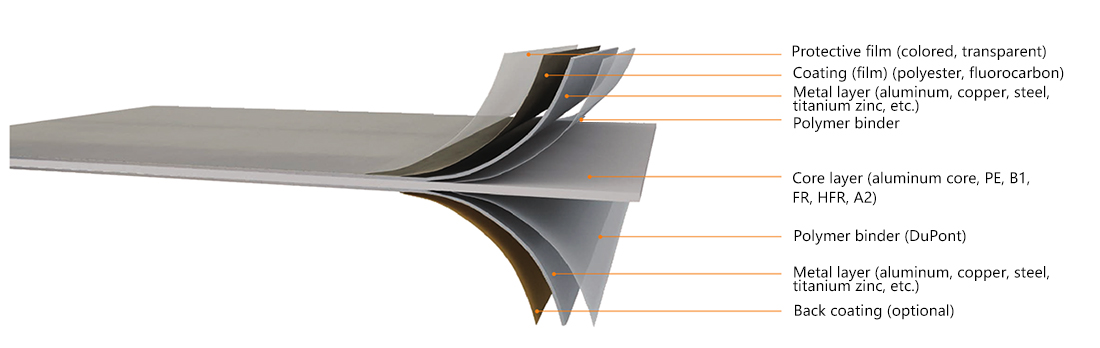

Metal composite panel is a decorative material that uses non-combustible inorganic materials as the core layer and metal skins on both sides as decorative surfaces. It is formed and composited through special processes.

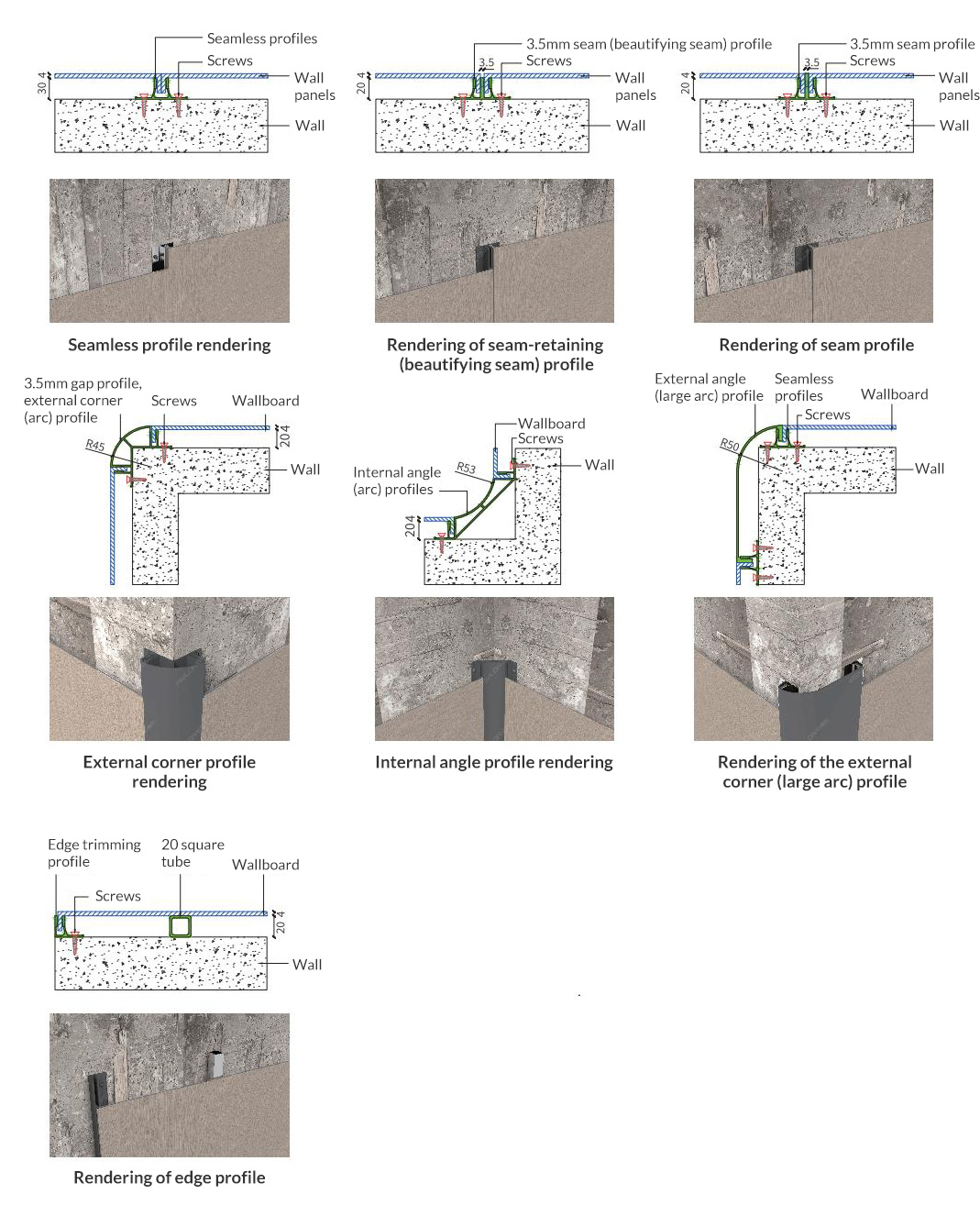

Metal composite panels have good safety performance, and their fire resistance reaches A2 level fire protection requirements. At the same time, they are easy to install and the construction is dust-free and noise-free.

Performance Parameters

| Test items | Standard requirement | Test result | Single conclusion | According to the standard | |

| Combustion performance level A (A2-S1, d0, t0) | Calorific value of main components (aluminum plate) | ≤3.0MJ/kg | 0MJ/kg | Conform to | GB/T 14402-2007 |

| Calorific value of main components (core material) | ≤3.0MJ/kg | 2.1MJ/Kg | Conform to | ||

| Calorific value of internal secondary components (polymer membrane) | ≤4.0MJ/㎡ | 3.3MJ/㎡ | Conform to | ||

| Calorific value of external secondary components (coating) | ≤4.0MJ/㎡ | 1.6MJ/㎡ | Conform to | ||

| Total heat of combustion | ≤3.0MJ/kg | 2.6MJ/kg | Conform to | ||

| Burning rapid killing growth index (FIGRA0.2MJ) | ≤120W/s | 12W/s | Conform to | GB/T 20284-2006 | |

| Total heat release in 600s | ≤7.5MJ | 1.2MJ | Conform to | ||

| Flame spreads laterally | Did not reach test long wing edge | Did not reach test long wing edge | Conform to | ||

| Total smoke production within 600 seconds | ≤50㎡ | 36㎡ | Conform to | ||

| Smoke generation rate index | <30m2/s2 | 1m2/s2 | Conform to | ||

| Combustion drippings/particles | No combustion dripping particles within 600s | No combustion dripping particles within 600s | Conform to | ||

| Toxicity of smoke production | Achieve quasi-safety level ZA1 | Achieve quasi-safety level ZA1 | Conform to | GB/T 20285-2006 | |

| Combustion sample installation instructions | 1. The specimen shall be installed in accordance with Article 5.2.2b) of GB/T20284-2006. 2. The back plate of the sample is a calcium silicate board with a thickness of 12mm and a density of 800kg/m’. 3. The fire-receiving surface of the sample is the decorative surface. |

||||

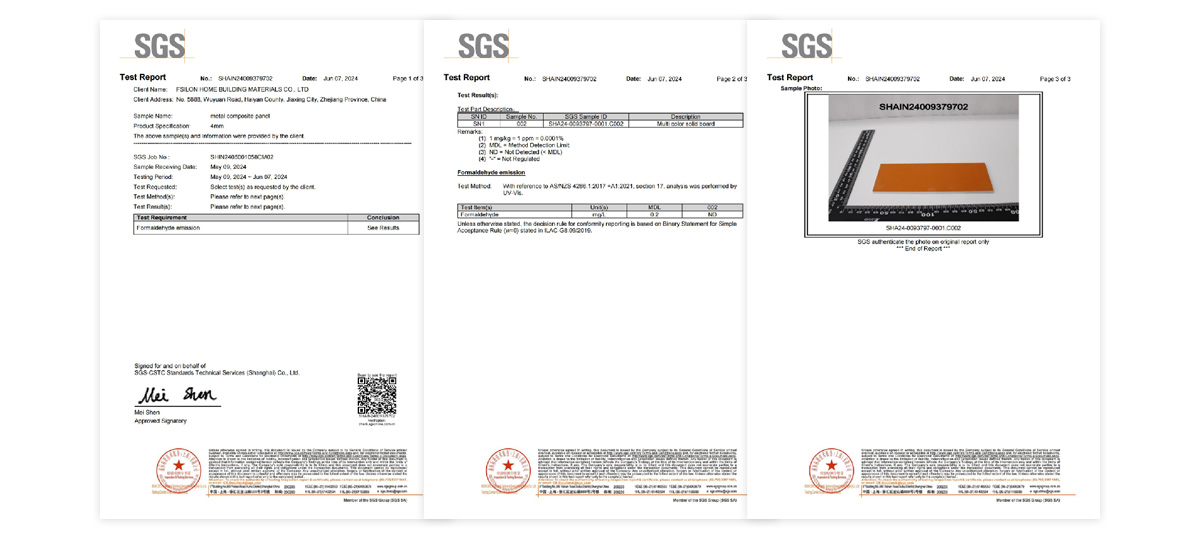

Formaldehyde Test Report

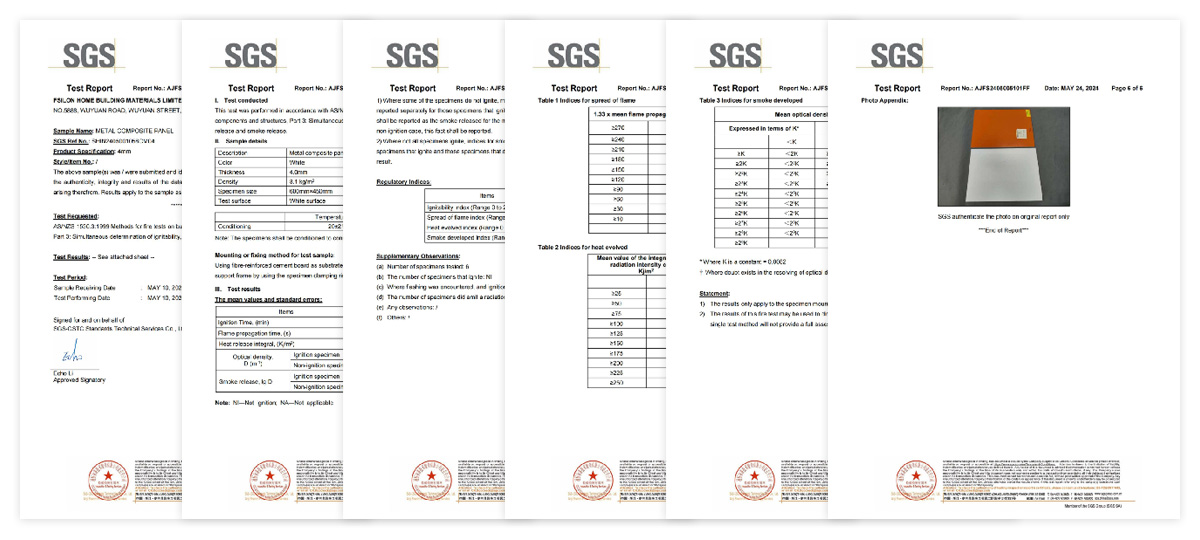

Flame Retardant Test Report

About Us

FSILON was founded in 2005. A leading prefabricated interior demonstration enterprise in China, listed on the main board of China A shares on August 3, 2020.

We are a one-step building materials enterprise that covers home decoration, engineering and commercial chain decoration. Our company provides R&D, production, manufacturing, sales, and gpod services. We are located in Haiyan, Zhejiang, China, with 260,000 square meters of super-large smart home industrial park.

As manufacturing sector expands globally, FSILON has seized new opportunities. By capitalizing on the advancements and industrial resources of home building materials industry, FSILON has established the FSL home building materials supply chain platform. This platform aims to offer overseas customers a one-stop-shop for sourcing and supplying home building materials, along with modular and turnkey solutions.

At present, FSL home building materials supply chain industry platform has provided business for customers from the United States, Bangladesh, Angola, Vietnam, Dubai, Zambilai and other countries and regions.

Capicity of Production

Related Products