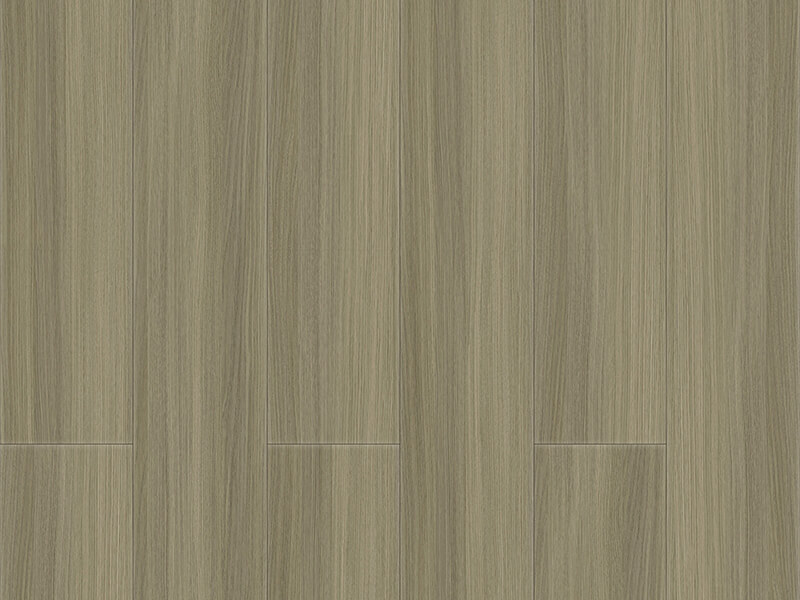

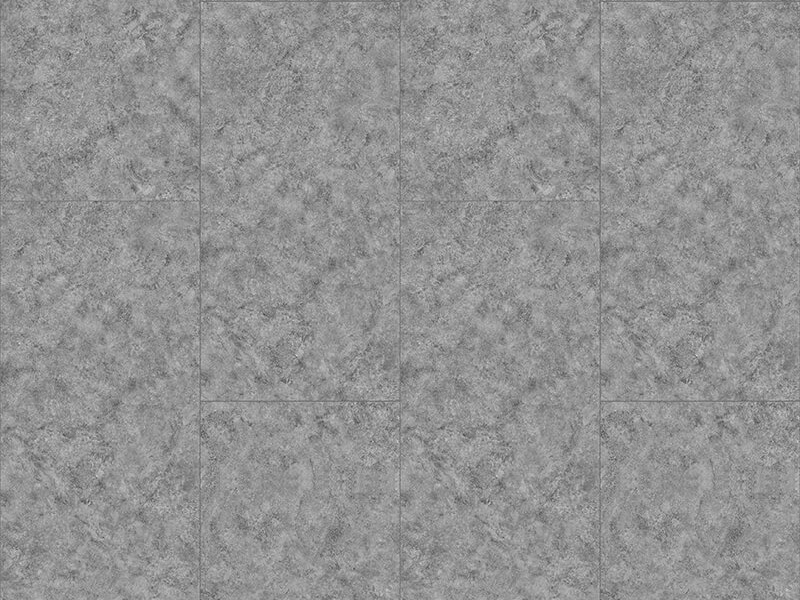

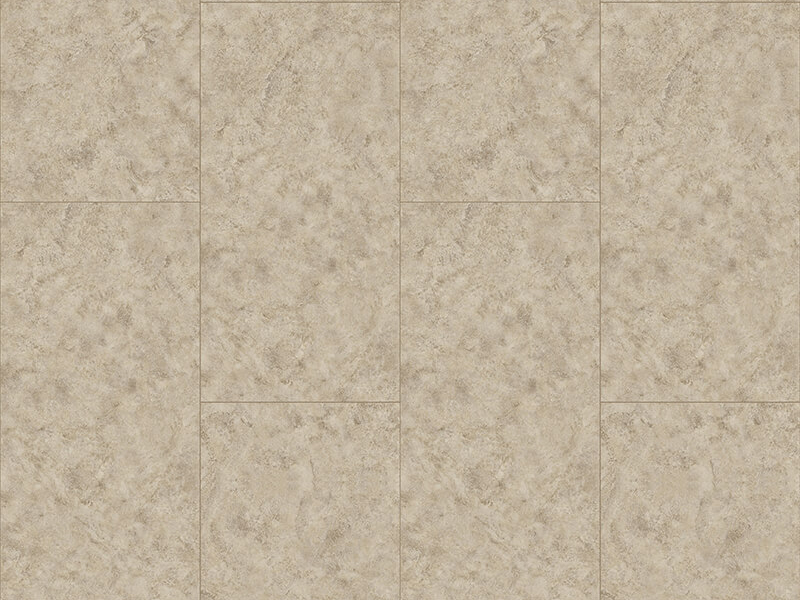

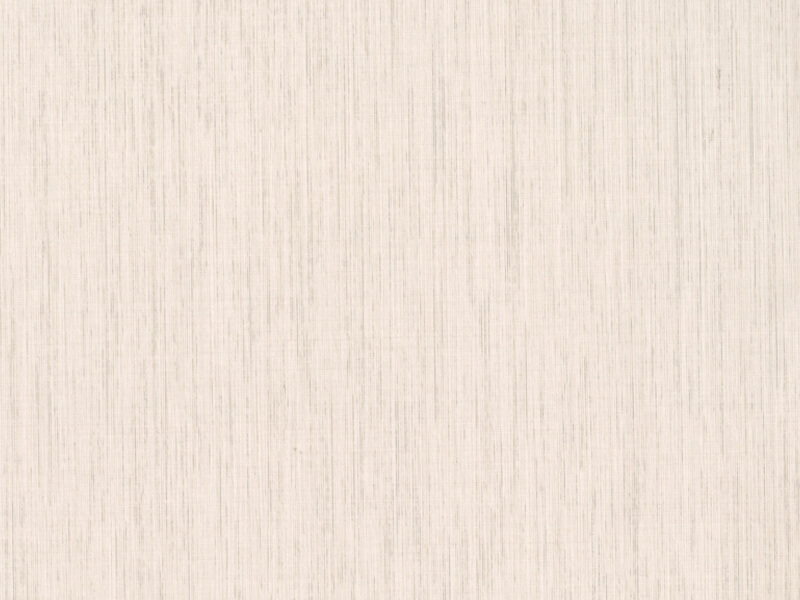

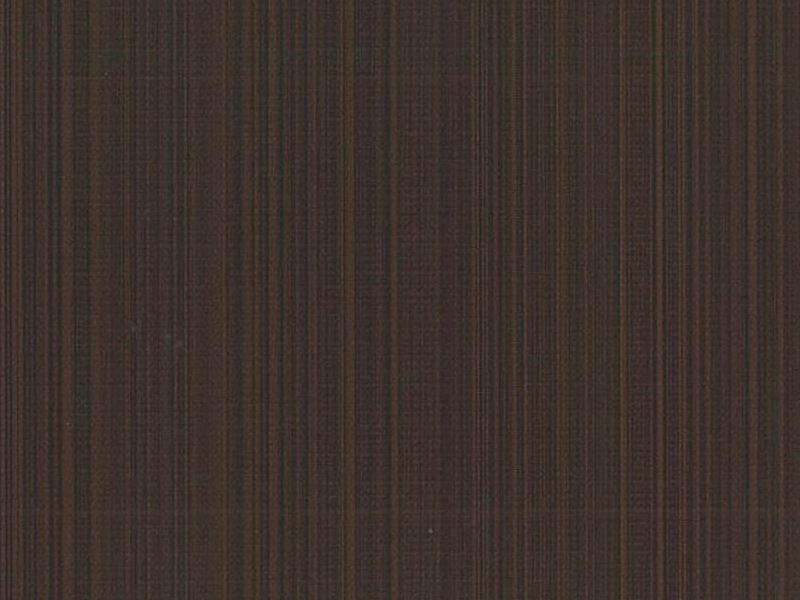

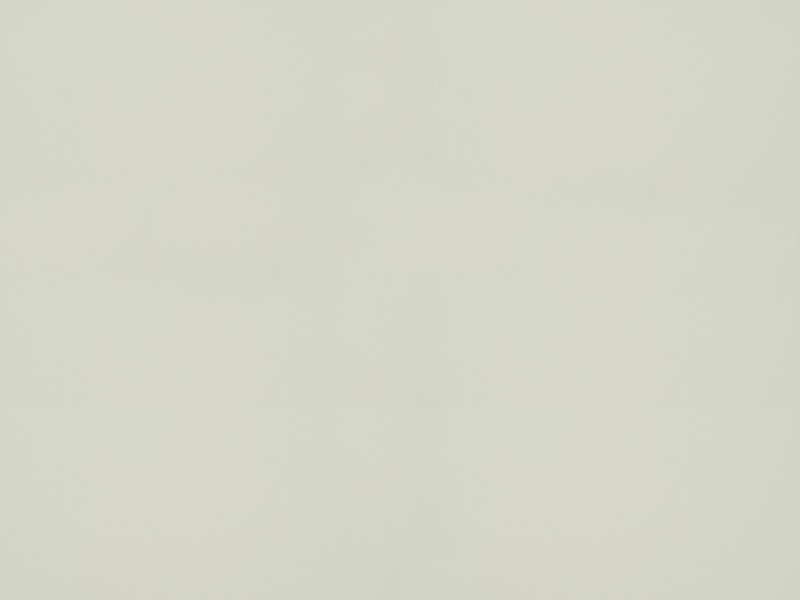

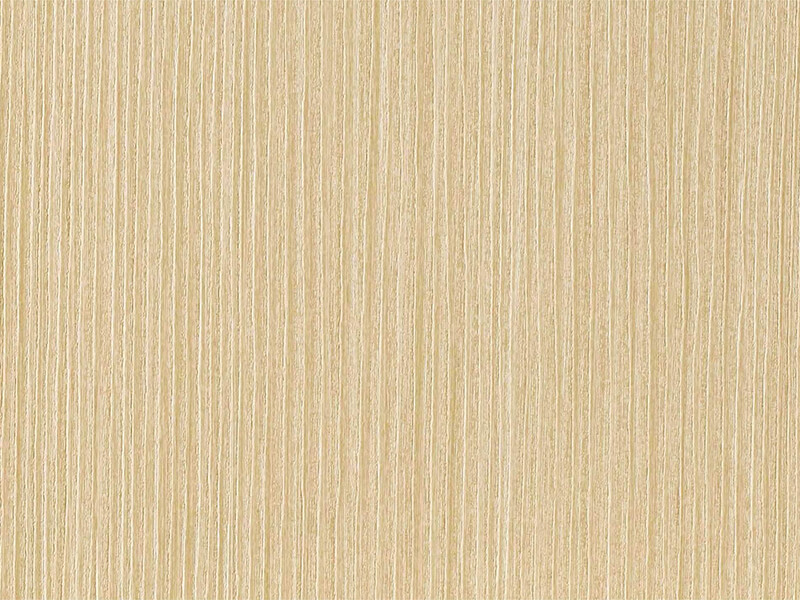

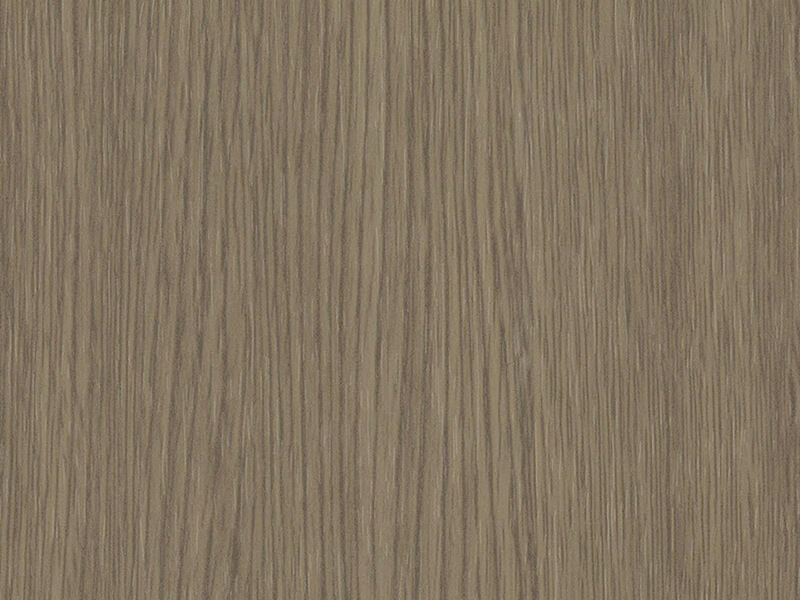

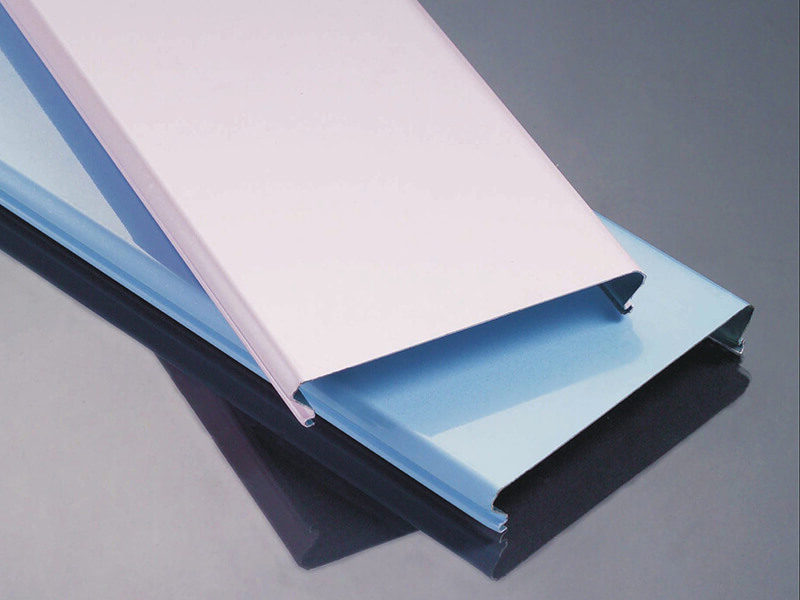

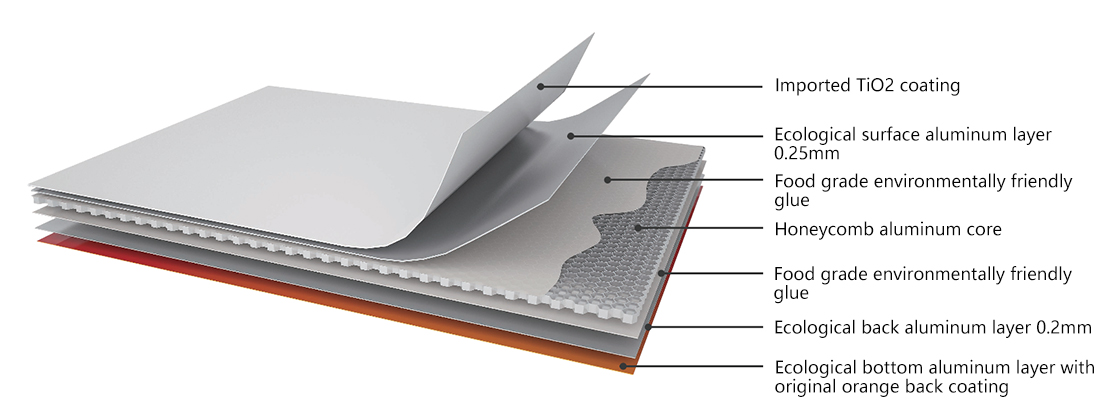

It adopts high-quality aluminum plate laminated with high-density honeycomb core technology. The structure adopts natural folding technology and natural seam splicing to achieve true micro-seam technology.

The surface coating is imported titanium dioxide, which has high stability, high hiding power, high durability, yellowing resistance, stable color matching, ultraviolet shielding, and high efficiency and scrub resistance.

The glossiness is ≤7° (close to latex paint), the texture is delicate, and the visual effect is elegant and soft.

Sound insulation, heat insulation and impact resistance, the overall density of 10mm is more scientific. After repeated testing by the R&D team, the thickness of 10mm without the aid of a frame has excellent sound insulation and

It has the best effect in terms of heat insulation and impact resistance, better flatness, and can also greatly improve space utilization.

It adopts high-quality aluminum plate laminated with high-density honeycomb core technology. The structure adopts natural folding technology and natural seam splicing to achieve true micro-seam technology.

The surface coating is imported titanium dioxide, which has high stability, high hiding power, high durability, yellowing resistance, stable color matching, ultraviolet shielding, and high efficiency and scrub resistance.

The glossiness is ≤7° (close to latex paint), the texture is delicate, and the visual effect is elegant and soft.

Sound insulation, heat insulation and impact resistance, the overall density of 10mm is more scientific. After repeated testing by the R&D team, the thickness of 10mm without the aid of a frame has excellent sound insulation and

It has the best effect in terms of heat insulation and impact resistance, better flatness, and can also greatly improve space utilization.

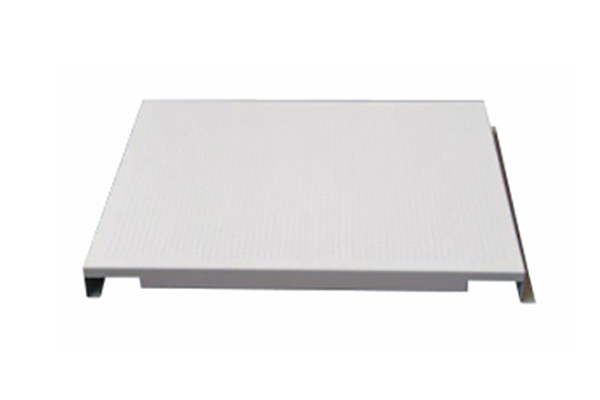

Product Description

Detail Shows

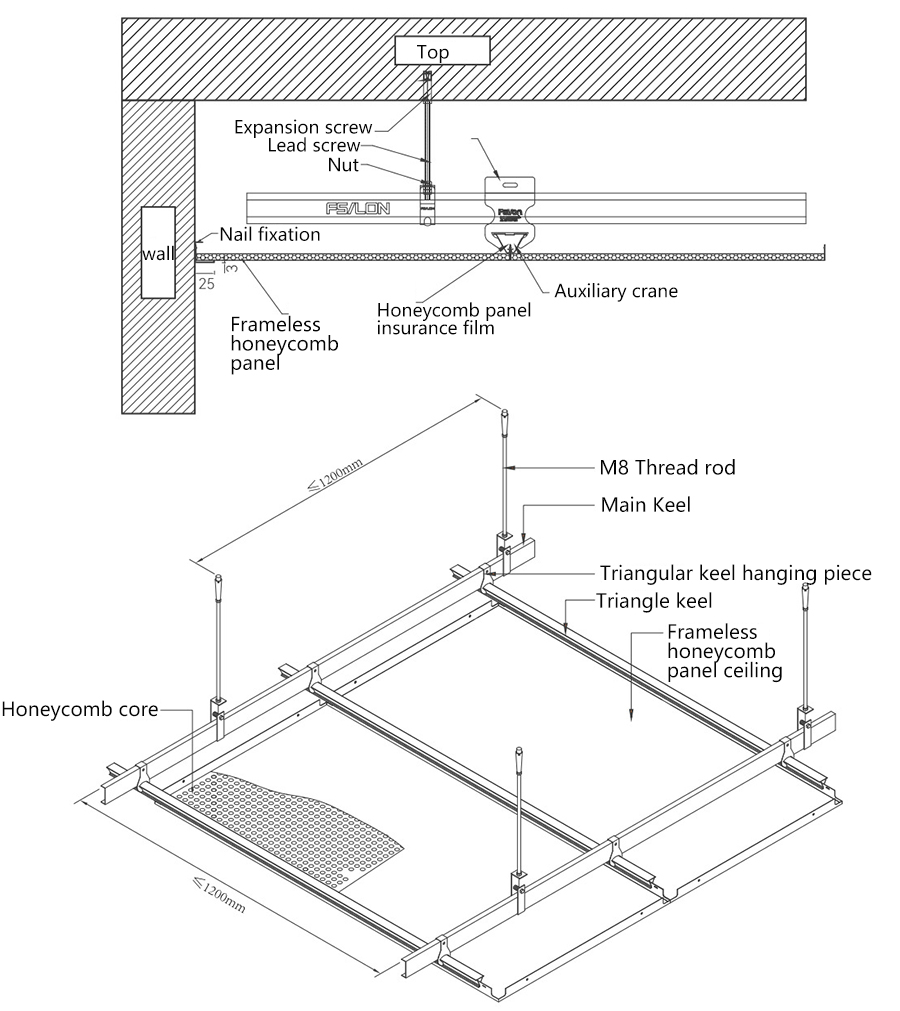

Install node graph

Install node graph

Performance Parameters

Performance Parameters

| Test items | Standard requirement | Test results | Single conclusion | Testing base | |

| Surface hardness | ≥HB | 2H (Zhonghua brand pencil) | Conform to | JC/T 2113-2012 7.7.1 GB/T 6739-2006 |

|

| Adhesion | Standard laboratory conditions | Level 0 | Level 0 | Conform to | Q/CYCTC 0110-2017 GB/T 17748-2008 7.7.4 GB/T 9286-1998(2004) |

| Hydrochloric acid resistance | No change | No change | Conform to | Q/CYCTC 0110-2017 GB/T 17748-2008 7.7.7 |

|

| Alkali resistance | No change | No change | Conform to | Q/CYCTC 0110-2017 GB/T 17748-2008 7.7.8 GB/T 11942-1989 |

|

| Flat tensile strength | Average value≥0.6Mpa; Minimum value≥0.4Mpa | Average 1.13Mpa Minimum value 0.97Mpa |

Conform to | JC/T 2113-2012 7.7.13 GB/T 1452-2005 |

|

| Flat compressive strength | ≥0.6Mpa | 1.07Mpa | Conform to | JC/T 2113-2012 7.7.13 GB/T 1455-2005 |

|

| Flat compression elastic modulus | ≥25Mpa | 45.3Mpa | Conform to | ||

| Plane shear strength | ≥0.4Mpa | 0.54Mpa | Conform to | JC/T 2113-2012 7.7.14 GB/T 1455-2005 |

|

| Plane shear elastic modulus | ≥3.0Mpa | 3.73Mpa | Conform to | ||

| Shear stiffness | ≥1.0x104N | 3.53x104N | Conform to | JC/T 2113-2012 7.7.15 GB/T 1456-2005 |

|

| Formaldehyde release (dryer method) | / | Not detected (<0.10mg/L) | / | GB/T 17657-2013 4.59 | |

About Us

FSILON was founded in 2005. A leading prefabricated interior demonstration enterprise in China, listed on the main board of China A shares on August 3, 2020.

We are a one-step building materials enterprise that covers home decoration, engineering and commercial chain decoration. Our company provides R&D, production, manufacturing, sales, and gpod services. We are located in Haiyan, Zhejiang, China, with 260,000 square meters of super-large smart home industrial park.

As manufacturing sector expands globally, FSILON has seized new opportunities. By capitalizing on the advancements and industrial resources of home building materials industry, FSILON has established the FSL home building materials supply chain platform. This platform aims to offer overseas customers a one-stop-shop for sourcing and supplying home building materials, along with modular and turnkey solutions.

At present, FSL home building materials supply chain industry platform has provided business for customers from the United States, Bangladesh, Angola, Vietnam, Dubai, Zambilai and other countries and regions.

Capicity of Production

Related Products